For a long time it was considered the number one scenario for AI and IoT applications in industry: predictive maintenance. However, companies that focus exclusively on predictive maintenance leave the enormous potential of AI and IoT largely untapped. The full value contribution of these technologies can only be realized when the entire production process is optimized on the basis of AIoT (Artificial Intelligence of Things). Device Insight and Sentian, a Swedish specialist in industrial AI, are pooling their expertise for this innovative approach. In our joint whitepaper we show companies how they can transform their production into a Smart Factory with the help of AIoT.

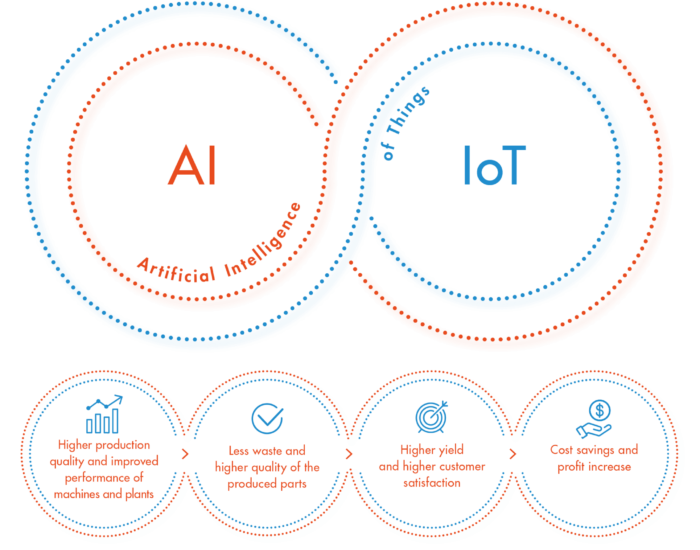

The combination of IoT and artificial intelligence offers companies numerous advantages.

Predictive maintenance is one of the most important and most discussed technologies at the interface of internet of things and artificial intelligence. Failures and maintenance requirements are to be predicted precisely, thus preventing the failure of machines and significantly reducing service and maintenance costs. However, if one takes a closer look at the industrial manufacturing process, one finds that predictive maintenance does not cover all AI scenarios by far. Here, AI and IoT merely act as “observers” and do not go beyond mere alarming in case of damage.

At the same time, AI and IoT technologies can contribute a much greater value to industrial production if one moves away from the focus on predictive maintenance and instead looks at the entire production. In fact, it is precisely the gradual improvements and fine adjustments of the manufacturing processes with AI and IoT that offer promising business value, with the prospect of an efficiency increase.

This is where Artificial Intelligence of Things (AIoT), e.g. the smart combination of artificial intelligence and IoT, comes in. The basic goal of the innovative approach of Device Insight and Swedish AI specialist Sentian is to significantly minimize variation from the optimum within the production process. Fewer deviations mean improved machine and system performance, less waste and lower costs – and above all, more highest-quality products. The result: income and profit, as well as customer satisfaction will increase noticeably. Production will be transformed into a smart factory. Companies that optimize their production processes with AIoT are able to increase the efficiency of their production by up to 30 percent.

One example is the German manufacturer of automation and sensor solutions JUMO. JUMO operates highly automated high-tech production facilities with advanced machines and many robots. Nevertheless, the company found that small but significant fluctuations occur within the production process. This led to deviations in the quality of the sensors produced and inevitably to a lower yield. With the help of intelligent automation – above all a special imputation model for missing data – the sensor accuracy could be increased significantly. In this way, JUMO was able to increase the proportion of sensors in the highest quality level by 20% and developed its production into a smart factory.

In order to use the full potential of intelligent automation, two technologies must be combined: Artificial intelligence and IoT. Only if well-maintained, high-quality data is available centrally, ML models can be applied on this basis for initiating a “learning process” within the production processes and deriving automated measures. To this end, Device Insight and Sentian bundle their know-how and accompany companies in a 5-step process on their way to becoming AIoT pioneers – from the analysis of the status quo and the IoT and AI readiness to the use case design, implementation, validation and company-wide integration and scaling.

The clear focus here is on the proof of value, i.e. the actual business added value that companies achieve through AIoT, and not – as is so often the case – on the purely technological feasibility, the proof of concept. At several points in the AIoT process, Go / No Go milestones are therefore provided at which – on the basis of clearly defined KPIs – a decision is made as to whether the proof of value has been achieved or whether adjustments need to be made. Through this clear documentation and an iterative, agile process of small steps, we ensure that companies really achieve their goals and the corresponding business value.

The free whitepaper will tell you more about the innovative AIoT approach and provide insights into real use cases.

Delivering excellence in IoT. We are an IoT Solution Provider for Smart Products, Connected Vehicles, Smart City, Smart Energy and Smart Production.